Behind every smartphone in your pocket, every medical device saving lives, and every precision component in modern automobiles lies a manufacturing revolution that most people have never heard of: Metal Injection Molding (MIM). This quiet transformation is reshaping how we create the intricate metal parts that power our modern world, one microscopic powder particle at a time.

The Hidden Architecture of Modern Life

Walk through any hospital, and you’ll encounter surgical instruments crafted through powder metallurgy injection moulding. Drive any modern vehicle, and transmission components shaped by metal injection moulding technology keep you moving safely down the road. Yet this manufacturing process remains largely invisible to the public eye, working behind the scenes to enable innovations that seemed impossible just decades ago.

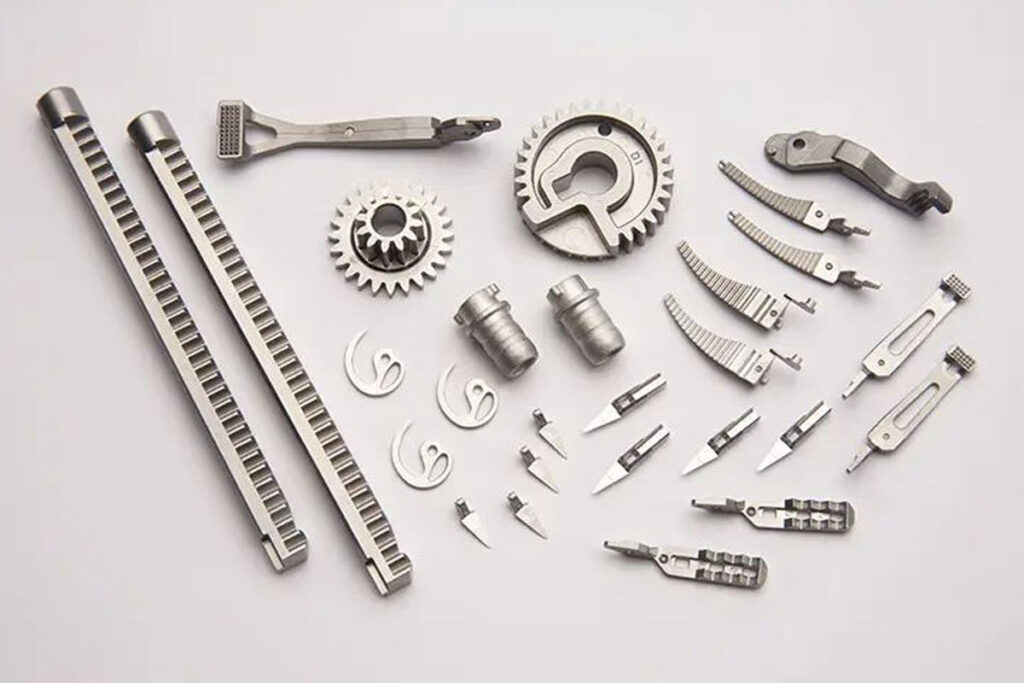

The story begins with something deceptively simple: metal powder so fine it feels like flour between your fingers. These particles, when mixed with polymer binders, become the raw material for a process that can create components previously requiring dozens of machining operations. It’s a transformation that speaks to humanity’s endless capacity for ingenuity.

Decoding the Manufacturing Alchemy

Understanding metal injection moulding requires appreciating its elegant simplicity masked by technical sophistication. The process unfolds like a carefully choreographed dance, where precision timing and temperature control determine success or failure.

Fine metal powders are first combined with thermoplastic binders, creating what engineers term “feedstock”, a material that flows like thick honey when heated. This mixture is then injected into precision moulds under tremendous pressure, forming what the industry calls “green parts.” These components possess their final shape but lack the strength of solid metal.

The true transformation occurs during debinding, where careful heat treatment removes the polymer binders, leaving behind porous “brown parts.” Finally, sintering fuses the metal particles in high-temperature furnaces, creating components that achieve remarkable density and strength.

Why Traditional Manufacturing Falls Short

Conventional metalworking often feels like sculpting marble with a sledgehammer when precision is paramount. Machining complex internal channels requires multiple setups, extensive tooling, and generates significant waste. Casting struggles with intricate geometries and often requires substantial finishing work.

Metal injection moulding technology sidesteps these limitations entirely:

• Geometric freedom: Internal channels, undercuts, and complex shapes emerge from moulds in single operations

- Material efficiency: Powder utilisation approaches 100%, dramatically reducing waste

- Surface quality: Parts emerge with smooth finishes requiring minimal post-processing

- Consistency: Every component maintains identical specifications across production runs

- Cost reduction: High-volume production becomes economically viable for complex parts

Singapore’s Manufacturing Renaissance

Singapore has positioned itself at the forefront of this manufacturing evolution, with advanced MIM facilities achieving international quality certifications and serving global markets. The nation’s commitment to precision engineering excellence has attracted manufacturers seeking both technical expertise and strategic location advantages.

Local industry specialists emphasise that metal injection moulding offers “a powerful solution for producing intricate metal components with high precision, making it an essential process for industries like automotive, medical, and consumer electronics.” This capability has enabled Singapore to become a critical supplier for sectors demanding the highest quality standards.

The country’s ISO-certified facilities demonstrate capabilities spanning from complex medical devices to aerospace components, establishing Singapore as a regional hub for advanced manufacturing technologies.

Industries Transformed by Innovation

The reach of MIM technology extends across virtually every sector of modern industry, each discovering unique applications for this versatile process.

Medical Device Revolution

Surgical instruments now feature internal channels for irrigation, brackets for orthodontic treatment achieve unprecedented precision, and implantable devices combine biocompatibility with complex geometries. The technology enables medical innovations that directly improve patient outcomes.

Automotive Evolution

From fuel injection components to transmission parts, MIM enables automotive manufacturers to reduce weight whilst increasing performance. Safety-critical components benefit from the consistent material properties that powder metallurgy delivers.

Consumer Electronics

The miniaturisation driving smartphone development relies heavily on MIM’s ability to create tiny, precise components. Camera modules, connectors, and structural elements all benefit from the technology’s unique capabilities.

Aerospace Applications

Where weight reduction can translate to millions in fuel savings, MIM creates components that maintain strength whilst minimising mass.

Confronting the Limitations

Every manufacturing technology faces constraints, and metal injection moulding presents its own set of challenges that manufacturers must carefully consider.

Investment requirements can be substantial, particularly for companies new to the technology. Specialised equipment, controlled atmospheres, and precision tooling demand significant capital commitment. Additionally, part size limitations restrict applications to components typically under 100 grams.

Lead times for new projects can extend for months, as mould development and process optimisation require patience and expertise. Material limitations also constrain applications, as highly reactive metals often prove unsuitable for standard MIM processing.

Environmental Stewardship Through Technology

Beyond its technical advantages, powder injection moulding technology offers compelling environmental benefits that align with sustainability goals. The minimal waste generation contrasts sharply with traditional machining, where material removal can exceed 90% in complex components.

Energy efficiency also favours MIM, as the process requires heating only during specific stages rather than maintaining molten metal throughout production. This efficiency translates to reduced carbon footprints and lower operational costs.

The Future Beckons

As global manufacturing continues evolving toward greater complexity and precision, metal injection moulding stands poised to play an increasingly vital role. Emerging materials, process refinements, and automation advances promise to expand the technology’s capabilities further.

The convergence of digital design tools with MIM capabilities enables innovations previously confined to imagination. Complex internal geometries, multi-material components, and integrated functionality all become achievable through this remarkable process.

For manufacturers seeking competitive advantages in an increasingly demanding marketplace, understanding and embracing MIM technology represents more than a manufacturing choice; it’s a strategic decision that can unlock possibilities previously considered impossible.

The quiet revolution continues, one precisely formed component at a time, as Metal Injection Molding (MIM) transforms our world in ways both profound and invisible, enabling the technologies that define modern life whilst pointing toward an even more innovative future.